|

Sales mode: distribution

Our polyolefin products are lifted by three shareholders including Fujian Petrochemical Company Limited, ExxonMobil China Petroleum & Petrochemical Company Limited, and Saudi Aramco Asia Company Limited according to their proportion of shares, and sold by distributors (Sinopec Chemical Sales Company South China Branch, ExxonMobil Chemical International Services (Shanghai) Limited, SABIC (Shanghai) Trading Co., Ltd.) designated by foregoing shareholders. Should you have any demand, please contact the corresponding shareholders/distributors for each product in the list (F: Fujian Petrochemical Company Limited; E: ExxonMobil Chemical International Services (Shanghai) Limited; S: SABIC (Shanghai) Trading Co., Ltd.).

FREP Marketing & Sales Department Polyolefin product consultation, technical support and after-sales service:

Mr. Chen:86(595)-27355741

Shareholders/distributors:

Operation Management Division of Fujian Petrochemical Company Limited

Address: Fulian Building, Anji Road, Fengze District, Quanzhou 362000, Fujian Province

86 (595)-2735 5209; 86 (595)-2735 5202; 86 (595)-2735 5203;传真:0595-2735 5200

Sinopec Chemical Sales Company South China Branch:

Manager Du:86 (595)-8267 2093

SABIC (Shanghai) Trading Co., Ltd.

Manager Li:13599920365

ExxonMobil Chemical International Services (Shanghai) Limited

86(21)23515000

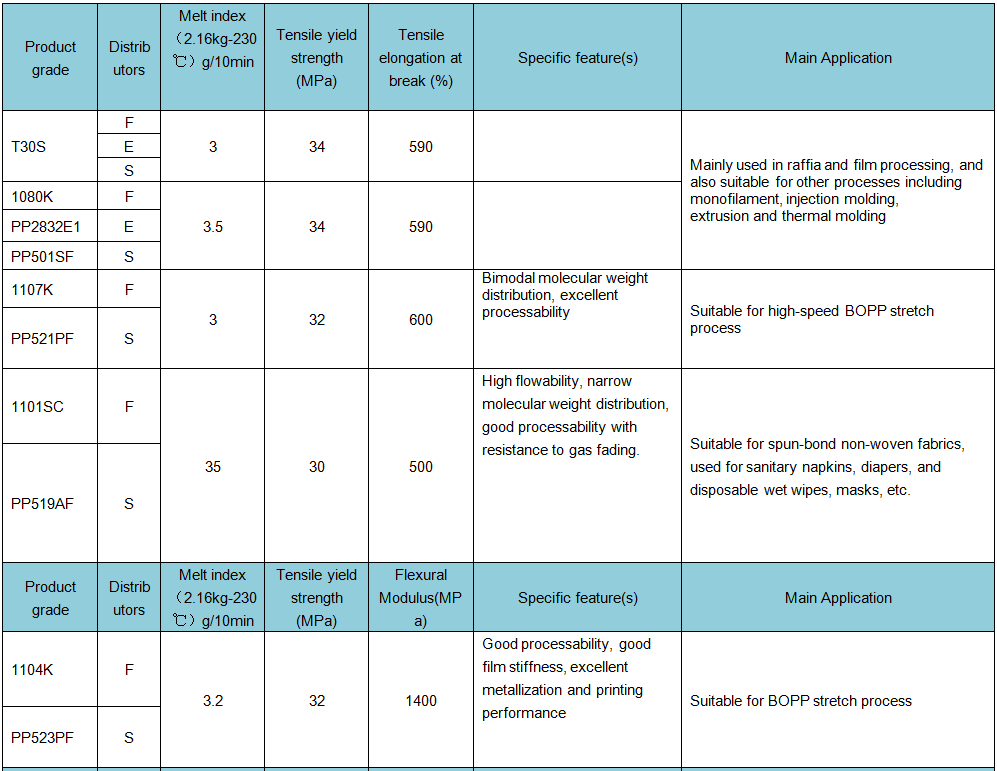

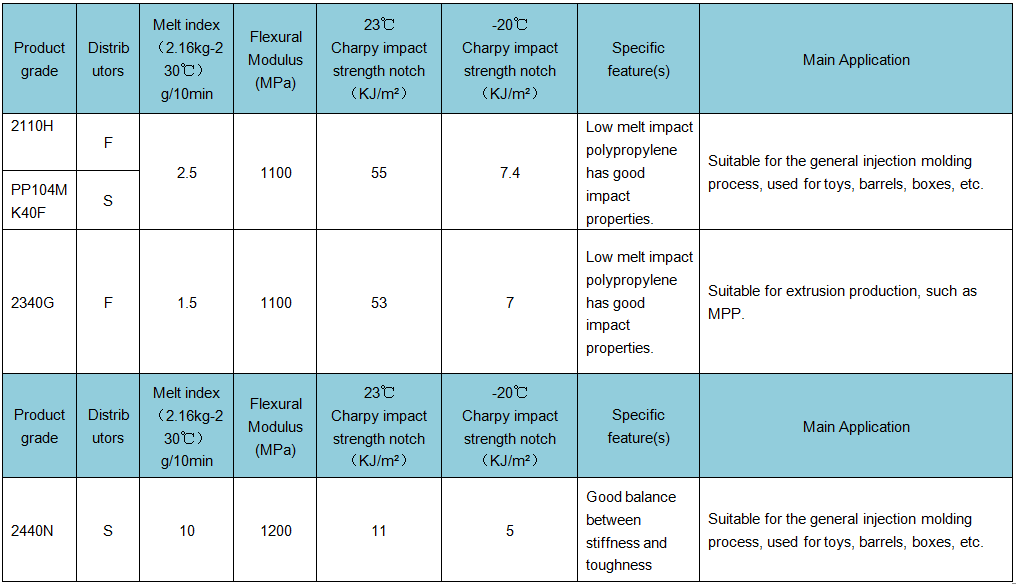

HOMO Polypropylene(HPP)

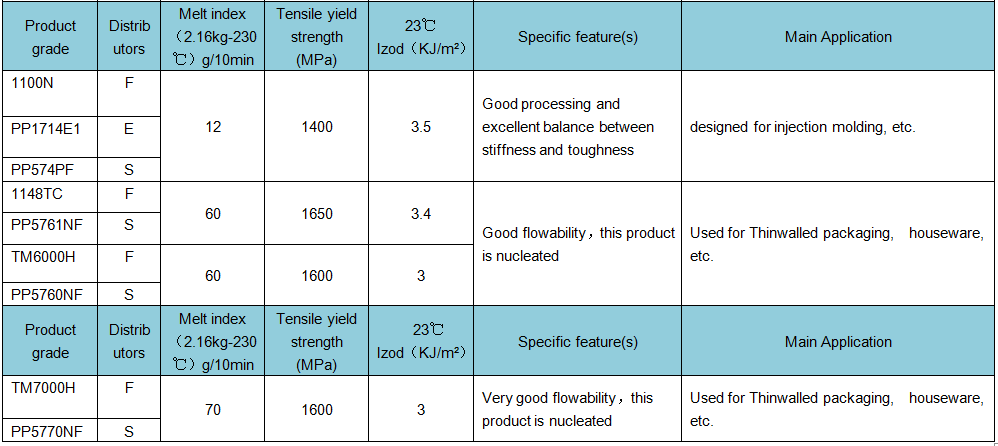

Polypropylene-block Copolymer(PPB)

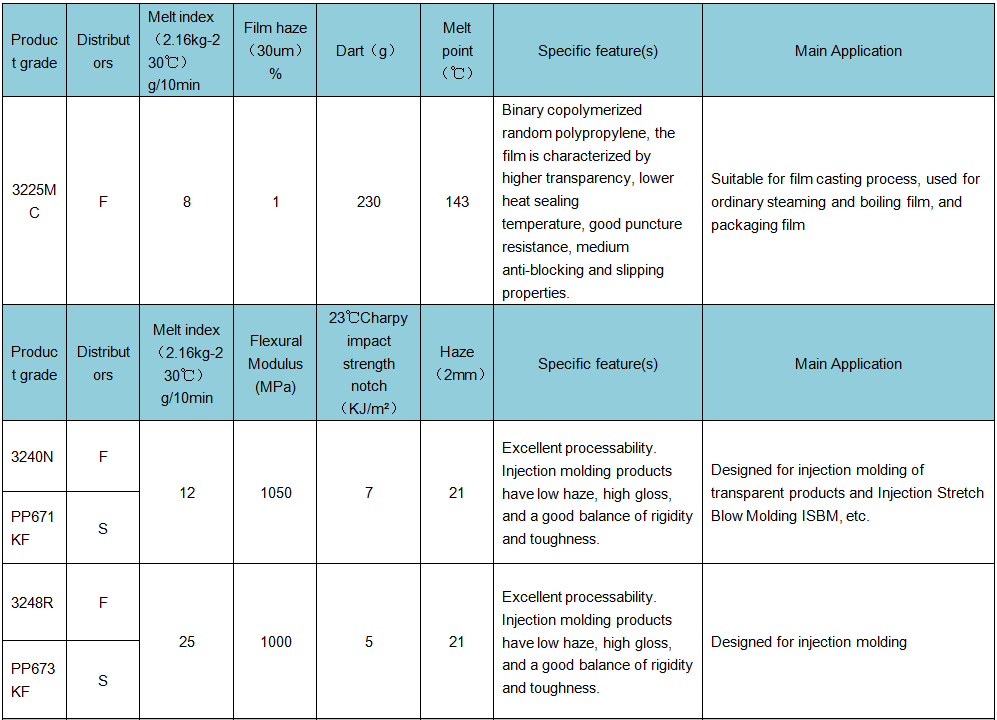

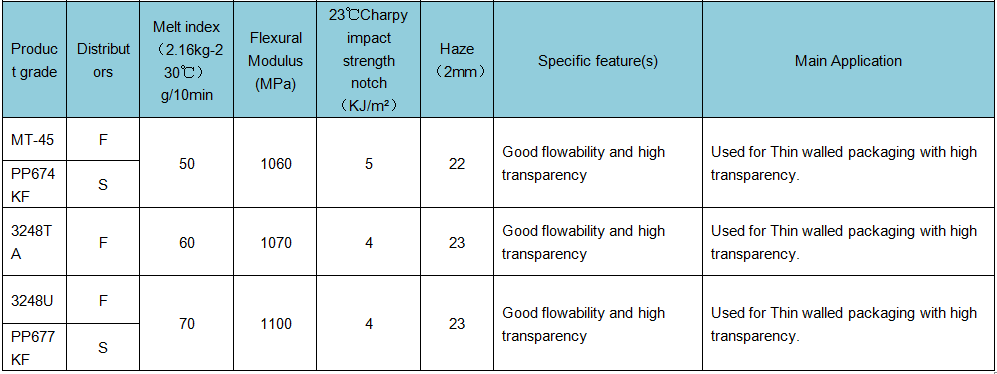

Random copolymer polypropylene(RCP)

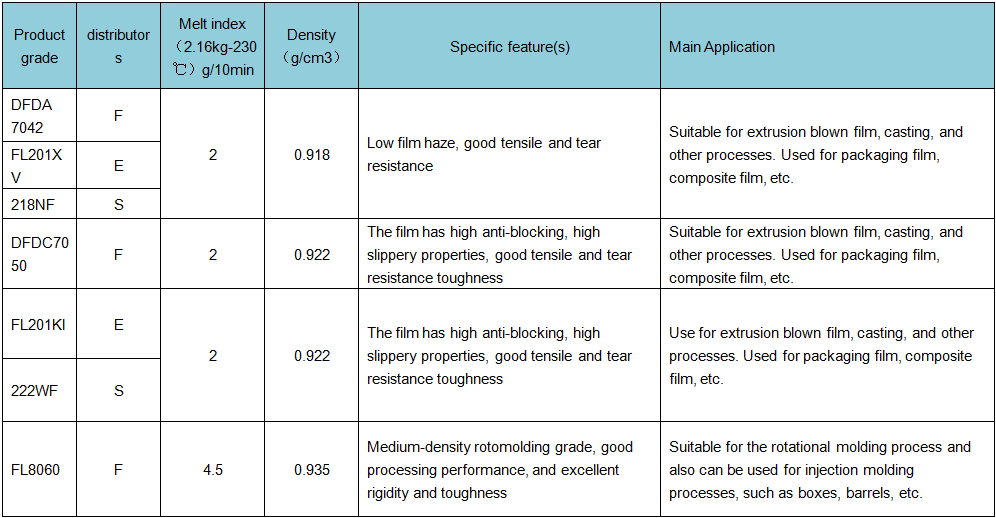

Linear Low Density Polyethylene(LLDPE)

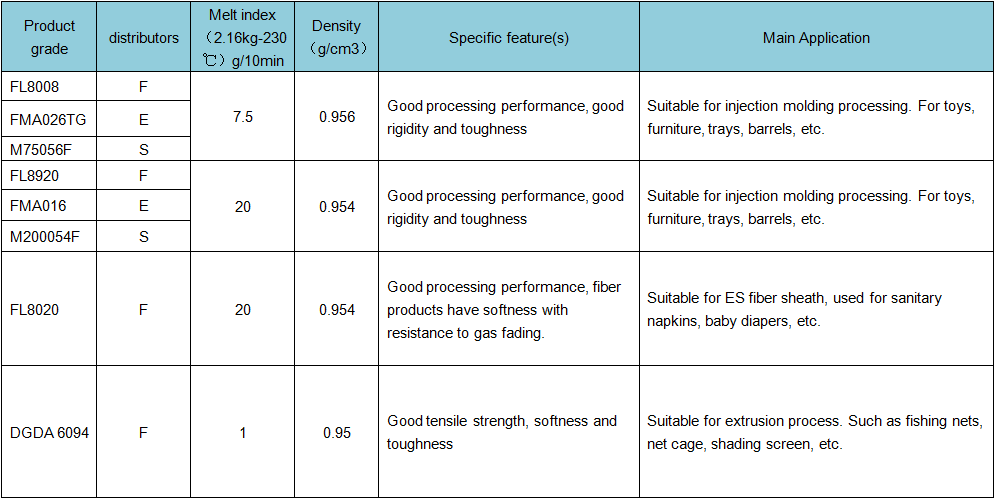

High Density Polyethylene(HDPE)

|